Rimac Technology, the engineering arm spun off from Croatian hypercar manufacturer Rimac in 2022, aims to revolutionize electric vehicles with significant advancements in solid-state batteries and high-performance powertrains.

Chief Operating Officer Nurdin Pitarevic, second-in-command to CEO Mate Rimac, outlined the company's focus on addressing key challenges faced by electric vehicles: extending driving range, enhancing fire safety, and drastically reducing charging times.

Rimac Technology is progressing rapidly in developing next-generation solid-state batteries (SSBs), collaborating with cell manufacturer ProLogium and composite specialists at Mitsubishi. Testing is expected to begin shortly, with the first application planned for a new Bugatti model in 2030. Although this timeline seems distant, the technology promises substantial benefits. The company anticipates that by 2035, the cost of these SSBs will be comparable to that of current battery cells.

The prototype solid-state battery pack showcases impressive improvements over traditional batteries. It offers a 100 kWh capacity, with energy density estimated to be 20 to 30 percent higher than conventional batteries of the same size. This increase allows more power storage within the same space. Additionally, the pack weighs around 30 kg less, thanks to an ultrastiff yet lightweight composite housing provided by Mitsubishi.

These new battery packs promise significant safety enhancements and support much faster charging. Rimac Technology is not targeting low-cost, mass-market electric vehicles; Pitarevic emphasized the company's focus on the premium, niche market. Volume production would only be considered if a major manufacturer licensed the technology for wider use.

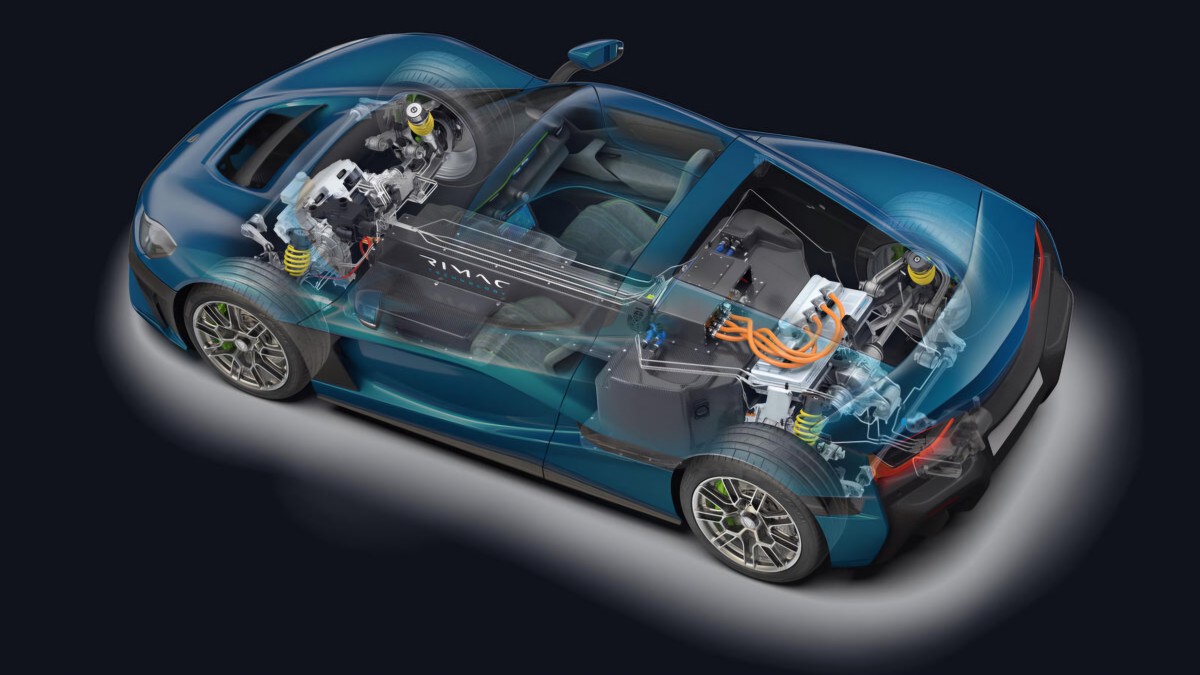

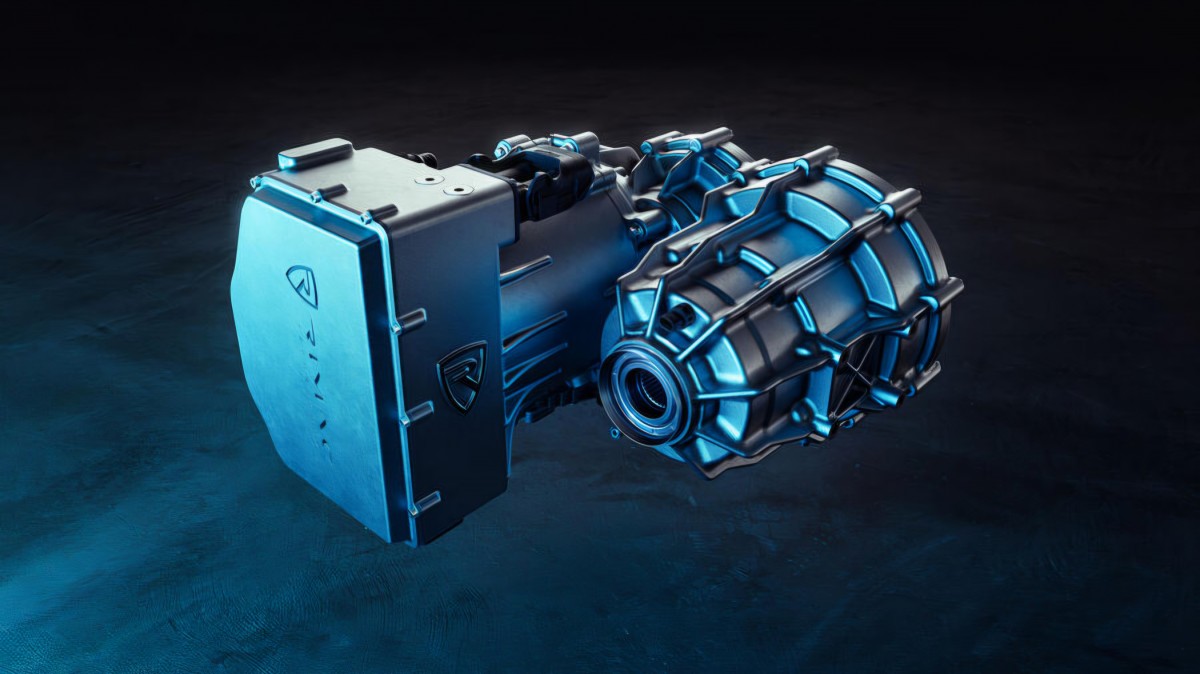

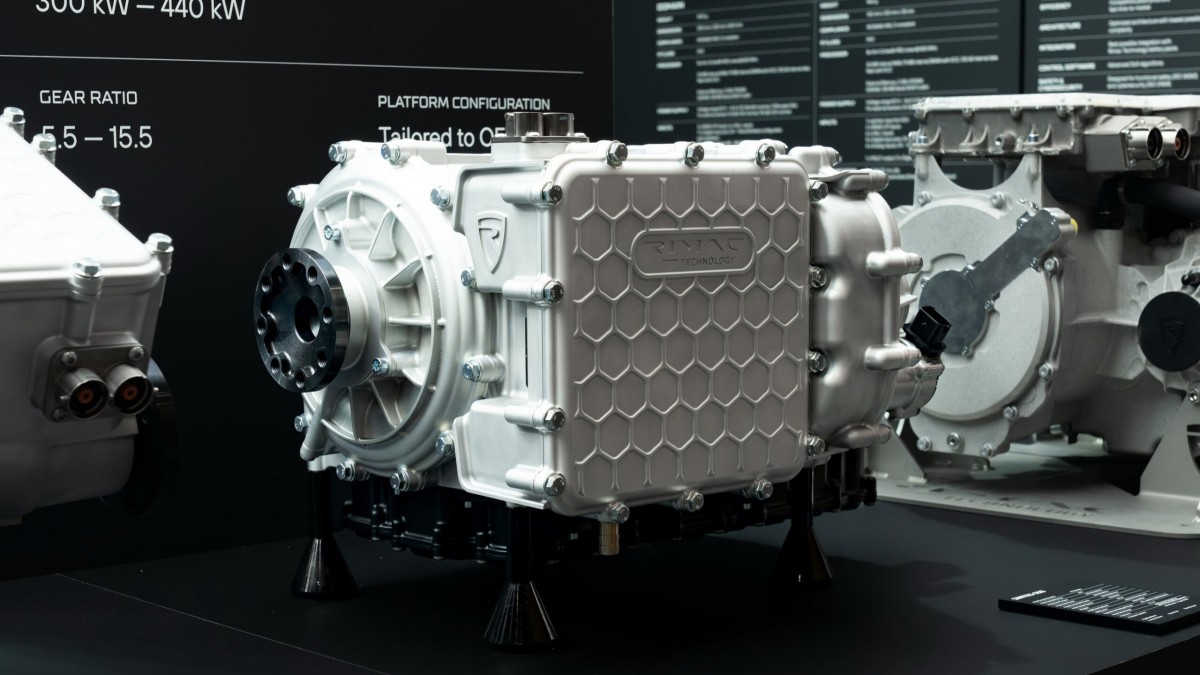

Beyond battery innovation, Rimac Technology is developing advanced e-axles, which integrate the electric motor, gearbox, and control electronics into compact, lightweight units adaptable to various drivetrain configurations—front-wheel drive, rear-wheel drive, or all-wheel drive. These e-axles are suitable for both hybrid and fully electric vehicles and deliver power outputs ranging from 149 kW to 350 kW (200 to 470 bhp).

Rimac’s clientele already includes global automakers such as BMW and Porsche, along with Saudi Arabian start-up CEER, plus several undisclosed partners.

The fast pace of Rimac’s e-axle development is evident in recent examples. For a powerful SUV being developed for CEER, Rimac is creating an e-axle with power and torque comparable to the rear-drive motor of the record-setting 1,288 bhp Nevera.

Despite delivering similar performance, the new CEER e-axle weighs just 291 lb—a notable reduction compared to the Nevera’s motor at 437 lb. For smaller, performance-oriented electric vehicles such as hot hatches or coupes, Rimac designed a suitcase-sized e-axle pack that delivers 373 kW (500 bhp) while weighing only 106 lb.

To support its growing innovation and production demands, Rimac is investing $351 million in a new production campus in Zagreb, Croatia. This facility will offer 95,000 m² of manufacturing space, enabling the company to produce tens of thousands of advanced components monthly.

Pitarevic, who has a background managing 10,000 employees across 22 factories, attributes Rimac’s success to its unique company culture. The firm fosters rapid decision-making, avoiding slow, email-driven processes.

CEO Mate Rimac aggressively encourages innovation, and the company benefits from having no legacy systems to restructure, allowing it to adopt the latest technologies from the outset. Furthermore, Croatia’s highly educated workforce and labor costs 20 to 30 percent lower than most Western European countries provide a competitive advantage, enabling this relatively young company to compete successfully against established industry giants.

Source