The world of internal combustion engines (ICE) is filled with numerous complex technologies: naturally aspirated engines, turbochargers, direct and indirect injection systems, various fuel types, and advanced cycles such as Atkinson, Miller, and Otto. This diversity exists primarily because no single design achieves perfect efficiency.

But does this complexity translate to electric vehicle motors? In fact, electric vehicles primarily use just three main types of motors. Let’s explore these motors, their operation, advantages, and disadvantages.

Asynchronous Induction Motor – A Historical Overview

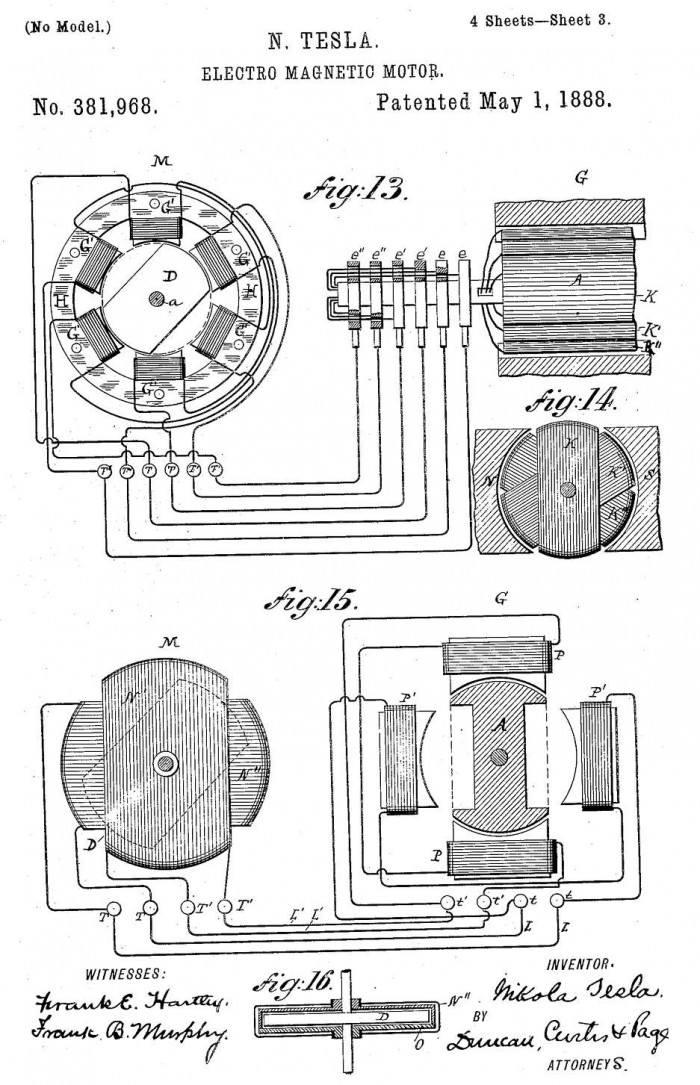

The asynchronous induction motor is not new; it was independently invented by Galileo Ferraris in 1885 and patented by Nikola Tesla in 1888. This invention revolutionized the use of electricity, powering countless devices and industrial machinery worldwide.

Nikola Tesla’s historic patent of the induction motor

Nikola Tesla’s historic patent of the induction motor

How Does an Asynchronous Induction Motor Work?

All electric motors consist of two main components: a stationary stator and a rotating rotor. The stator, typically a steel cylinder with slots filled with copper coils, is energized by a three-phase alternating current (AC) supplied via an inverter converting the battery’s direct current (DC). This generates a rotating magnetic field in the stator at a speed called the synchronous speed.

The rotating magnetic field induces voltage in the rotor, generating current that produces its own magnetic field. This rotor magnetic field lags the stator’s field, creating a force known as the Lorentz force which causes the rotor to turn. This torque is then transmitted to the vehicle’s wheels through the drivetrain.

The motor is termed asynchronous because the rotor’s magnetic field does not exactly synchronize with the stator’s rotating field, causing a slight difference called “slip,” typically up to 5%. During regenerative braking, the rotor field leads the stator field, enabling energy recovery.

Asynchronous motors boast around 90% efficiency, are robust, simple, long-lasting, and do not require rare earth materials. Their good overload capacity makes them ideal for applications demanding quick on-demand power, commonly used as front motors in all-wheel drive (AWD) electric vehicles.

Pros

- Good efficiency

- Low cost of manufacture

- No reliance on rare earth materials

- High reliability

Cons

- Higher cooling requirements

- Lower power density

- Less efficient compared to other motor types

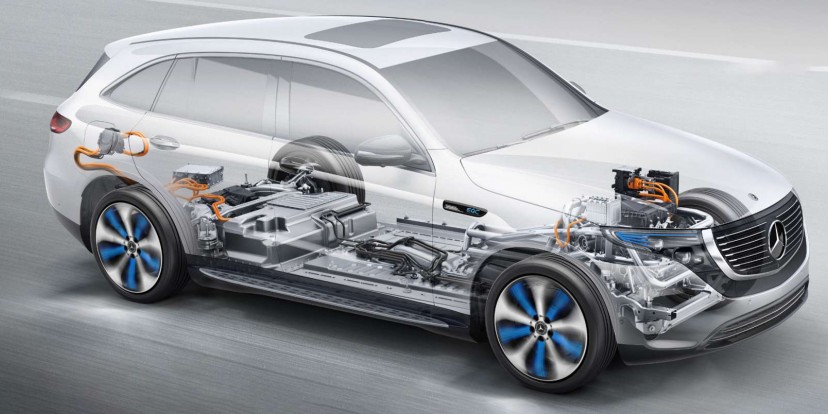

Examples of vehicles using asynchronous induction motors include the Audi e-Tron SUV, Mercedes-Benz EQC, Tesla Model S, Model 3, Model X, Model Y (front axles), and various VW Group MEB platform vehicles (front axles).

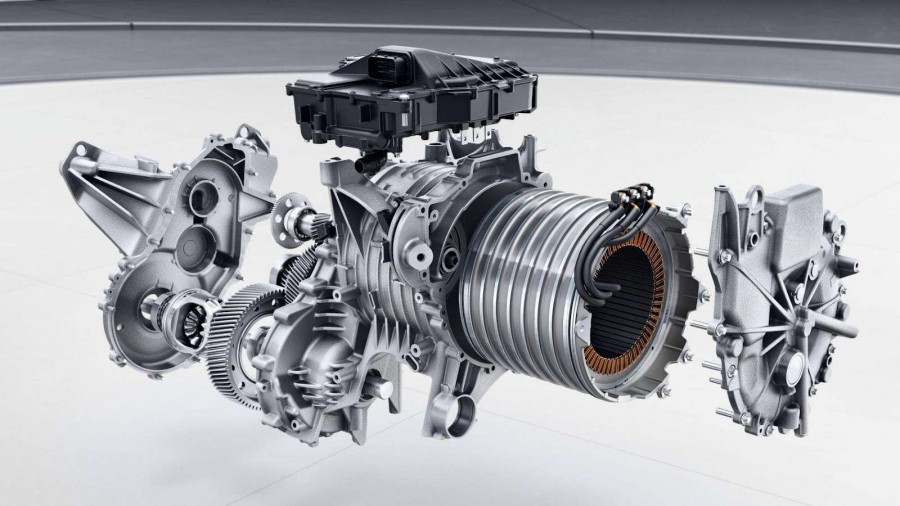

Induction motor used in Mercedes-Benz EQC

Induction motor used in Mercedes-Benz EQC

Synchronous Permanent Magnet Motor

The key distinction of the synchronous permanent magnet motor is the rotor’s magnetic field, which is generated by permanent magnets rather than induction. This causes the rotor and stator magnetic fields to be locked in sync, eliminating slip.

The use of permanent magnets significantly improves power density and efficiency, reaching up to 94-95%. Their compactness makes them ideal for plug-in hybrids (PHEVs) where space constraints exist, such as within gearboxes.

However, permanent magnets require rare earth elements predominantly sourced from China, raising ethical and supply chain concerns. Despite this, the synchronous permanent magnet motor remains the most efficient and is typically used when a single motor drives the vehicle.

Pros

- Exceptional efficiency

- Lower cooling requirements

- High power density

Cons

- Higher manufacturing costs

- Dependency on rare earth materials

- Potential risk of demagnetization

Hyundai Ioniq 5 permanent magnet motors

Hyundai Ioniq 5 permanent magnet motors

Vehicles using synchronous permanent magnet motors include the Hyundai Ioniq 5, Tesla Model S, 3, X, and Y (rear axles), various VW Group MEB vehicles (rear axles), Jaguar I-Pace, Audi e-tron GT, and Porsche Taycan.

Electrically Excited Synchronous Motor

To mitigate the challenges posed by rare earth dependency, some manufacturers such as BMW, Renault Group, and Smart have adopted electrically excited synchronous motors. These use electromagnets on the rotor powered through brushes and slip rings instead of permanent magnets.

This design achieves efficiencies up to 93%, closely matching permanent magnet motors while eliminating the need for rare earth materials and avoiding demagnetization risks. However, the presence of brushes limits long-term durability since they require eventual replacement.

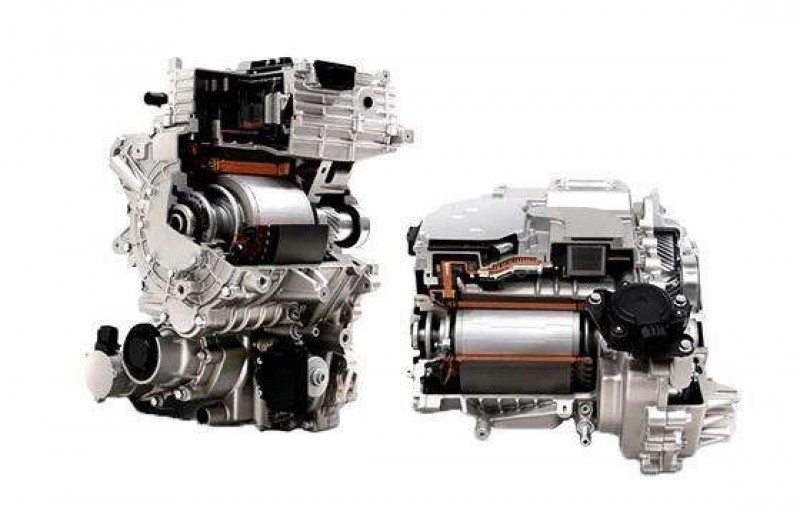

BMW electrically excited synchronous motor

BMW electrically excited synchronous motor

Pros

- High efficiency

- Lower production costs than permanent magnet synchronous motors

- No need for rare earth materials

- No risk of demagnetization

Cons

- Brushes require maintenance or replacement

This motor type powers the BMW iX3, iX, i4, Renault Megane E-TECH, and Smart EQ models.