Samsung is embarking on a mission to design and build custom application processors (APs) tailored specifically for its Galaxy smartphone lineup. By controlling the entire process from design to manufacturing through its own foundry, Samsung hopes to enhance battery life, boost performance, and improve efficiency in its devices.

Leveraging In-House Foundry Capabilities to Outperform Competitors

Owning a semiconductor foundry gives Samsung a unique advantage over many fabless chipmakers. This vertical integration enables Samsung to oversee the complete system-on-chip (SoC) creation from concept to production. Unlike Apple, which currently depends on TSMC for its chip manufacturing—and is rumored to be considering Intel for some future iPhone SoCs—Samsung controls every step of its chip manufacturing pipeline.

Historically, Samsung’s Exynos chips have faced challenges related to overheating and power efficiency, prompting the company to rely on Qualcomm’s processors for flagship Galaxy devices in key markets like the U.S. and China. For instance, despite Samsung’s design of the Exynos 2500, manufacturing setbacks at its foundry restricted supply, leading the Galaxy S25 series to use Qualcomm’s Snapdragon 8 Elite exclusively.

The Exynos 2600: A Leap Toward 2nm Process Technology

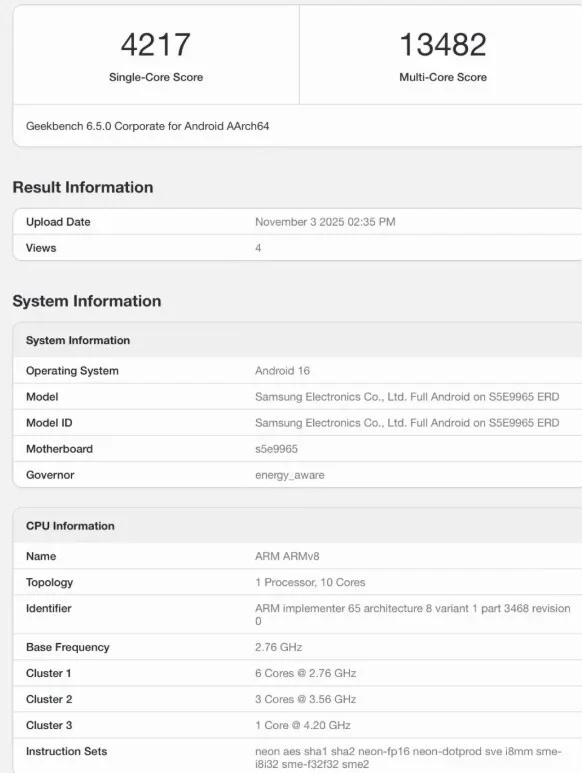

Production yield issues plagued Samsung Foundry since 2022, impacting its ability to manufacture Snapdragon processors and its own Exynos chips. Samsung reportedly incurred an additional $400 million cost to acquire enough Snapdragon chips for devices initially scheduled to run on Exynos 2500 APs. However, improvements in yield this year have enabled Samsung to develop and benchmark the Exynos 2600, potentially the world’s first 2nm application processor for smartphones.

The 2nm fabrication process allows for smaller transistor features and higher density, enabling chips with greater power and energy efficiency. Although Samsung’s 2nm Gate-All-Around (GAA) transistor density—estimated between 300 and 320 million transistors per square millimeter—is less than TSMC’s anticipated 400 million, the new architecture promises significant performance and efficiency gains.

The Exynos 2600 demonstrated impressive benchmark results. | Image credit: Wccftech

On-Device AI Processing and Cost Benefits Through Custom Chips

With the GAA transistor technology that surrounds the channel on all four sides, Samsung’s upcoming chips are expected to reduce current leakage and improve power management. This advancement could allow Galaxy devices to execute more AI tasks locally, minimizing reliance on cloud processing. Samsung also anticipates that designing its own application processors will help reduce production costs, enabling more competitively priced Galaxy handsets without compromising profitability.

Potential for Expansion Beyond Smartphones

Industry experts believe that success in custom smartphone chip development could lead Samsung to extend this expertise to other product lines like wearables and PCs, following in Apple’s footsteps. Increasing in-house chip demand may boost Samsung Foundry’s yield improvements and gradually challenge TSMC’s dominant market share, which currently stands near 70-71%, while Samsung holds about 8%.

Given Samsung’s proven track record in manufacturing DRAM and image processing chips, many see no fundamental obstacle to the company eventually mastering application processors and supplying its own flagship Galaxy handsets. The path forward will require substantial effort and the assembly of a skilled SoC design team capable of meeting flagship-level performance standards.