The Galaxy Z TriFold represents Samsung’s flagship foldable smartphone and showcases impressive engineering innovation. While we touched on some aspects in our announcement coverage, Samsung has now released an official video revealing the detailed assembly and comprehensive testing process designed to guarantee the Z TriFold’s dependable daily performance.

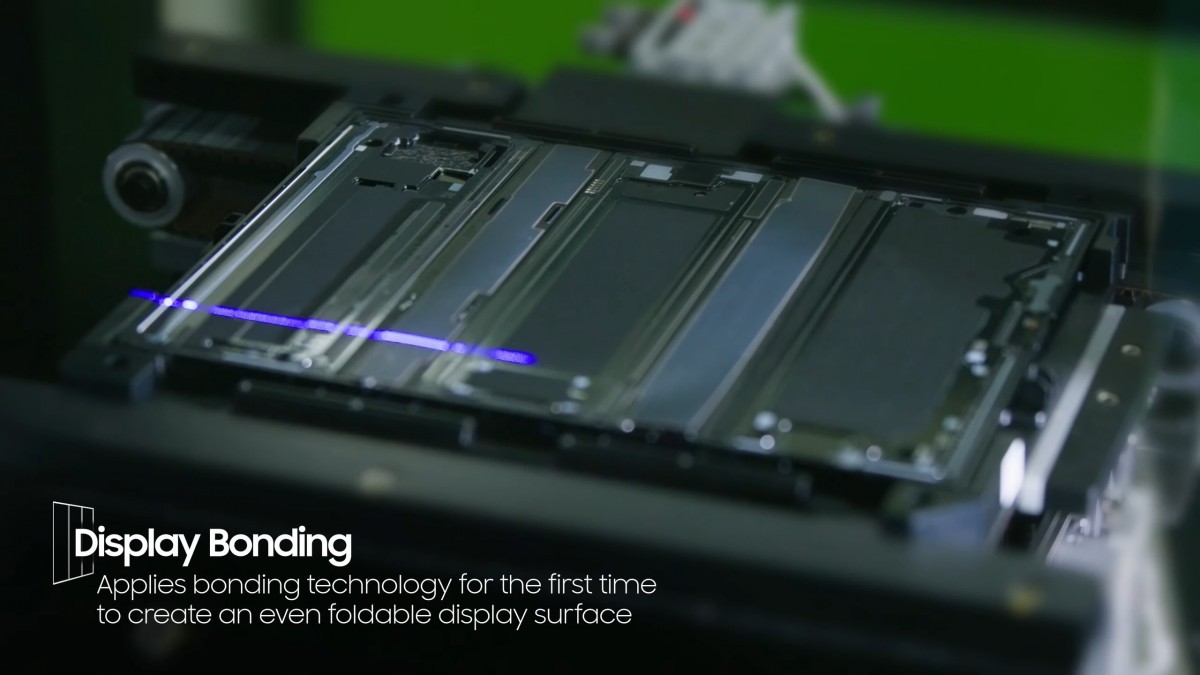

Building on a decade of foldable smartphone expertise, Samsung begins with a titanium hinge assembly featuring two Armor Flex Hinges. The company employs an automated assembly line combined with 3D laser scanning to ensure the main display meets strict quality standards.

To validate durability, Samsung subjects the main display to a 200,000-cycle folding test, simulating 100 folds per day over five years.

The Z TriFold also undergoes a high-speed CT scan to inspect critical internal components such as the flexible printed circuit board, ensuring all structural requirements are met. Subsequently, the device’s cameras are tested for sharpness and performance.

Additionally, Samsung performs a “real-world scenario test” that simulates active usage conditions covering network performance, battery life, display functionality, and environmental factors.

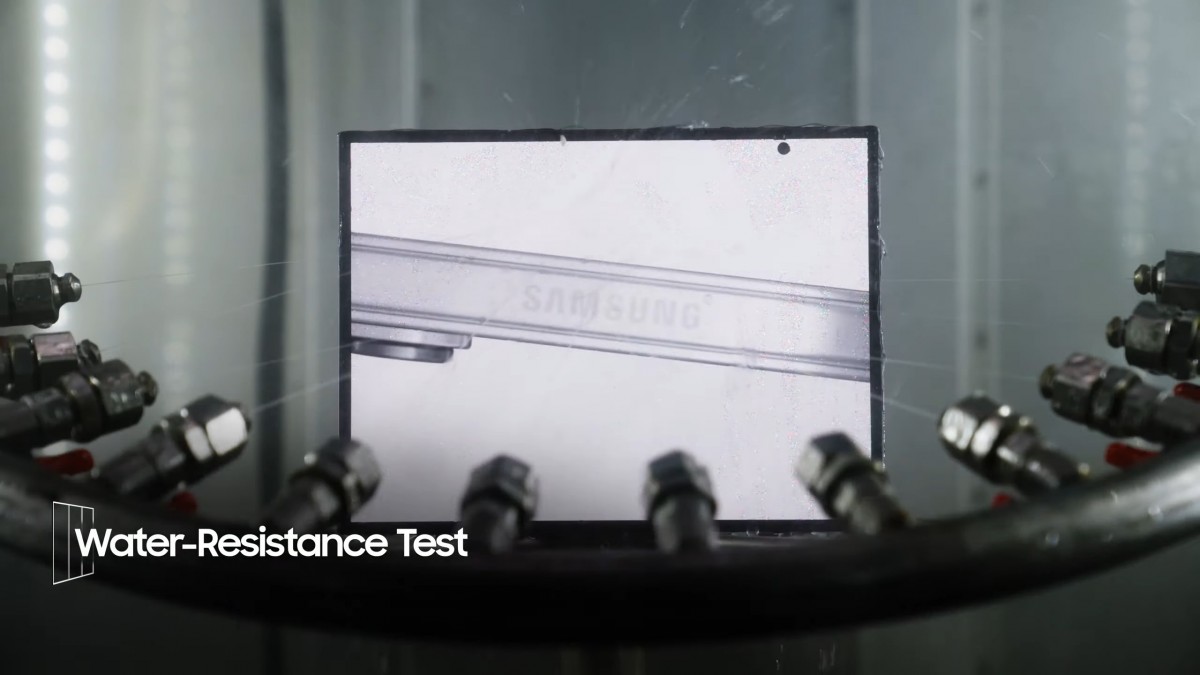

Finally, the device’s IPX8 water resistance is verified by exposing it to water jets from multiple angles, confirming its reliability against water exposure.