Diving into internal combustion engine technology often involves navigating a complex array of concepts—such as naturally aspirated and turbocharged engines, various injection methods, fuel types, and numerous engine cycles and turbo configurations. This variety arises because no single combustion design achieves optimal efficiency, leading engineers to innovate continuously.

In contrast, electric vehicles (EVs) rely on far fewer motor types. In fact, there are mainly just three types of electric motors powering e-mobility today. Let’s explore these key motor technologies.

Asynchronous Induction Motor: A Brief History

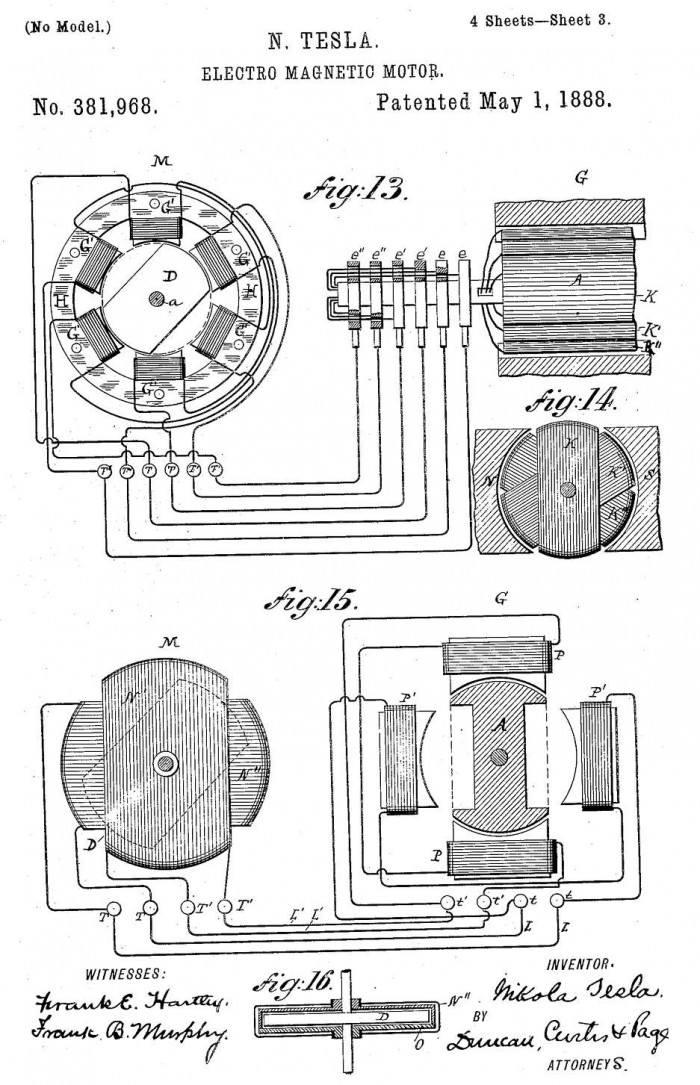

The asynchronous induction motor is a well-established technology, independently invented by Galileo Ferraris in 1885 and Nikola Tesla, who patented it in 1888. This invention stands as a milestone in electrification and remains ubiquitous today.

Induction motors power countless electric devices and dominate industrial applications due to their robustness and reliability.

Nikola Tesla’s historic patent of the induction motor

Nikola Tesla’s historic patent of the induction motorHow Do Asynchronous Induction Motors Work?

Electric motors consist of two main parts: a stationary stator and a rotating rotor. The stator is typically a steel cylinder embedded with copper coils arranged in a specific geometry. These coils are energized with three-phase alternating current (AC) converted from the battery’s direct current (DC) through power electronics, creating a rotating magnetic field known as synchronous speed.

The rotating field induces current in the rotor, generating its own magnetic field that lags behind the stator’s field. The interaction between these fields produces the Lorentz force, causing the rotor to turn. This motion is transmitted to the vehicle’s wheels via a reduction mechanism.

Named “asynchronous” because the rotor’s magnetic field does not synchronize perfectly with the stator’s, the motor experiences a slip—typically up to 5%. This slip varies with operation, such as during acceleration or regenerative braking.

Industry-standard 3-phase asynchronous induction motors achieve approximately 90% efficiency. Their durability, simplicity, and lack of exotic materials make them ideal for industrial use and as front motors in all-wheel-drive EVs.

Advantages

- Good efficiency

- Cost-effective manufacturing

- No reliance on rare earth materials

- Exceptional reliability

Disadvantages

- Higher cooling requirements

- Lower power density compared to alternatives

- Somewhat lower efficiency

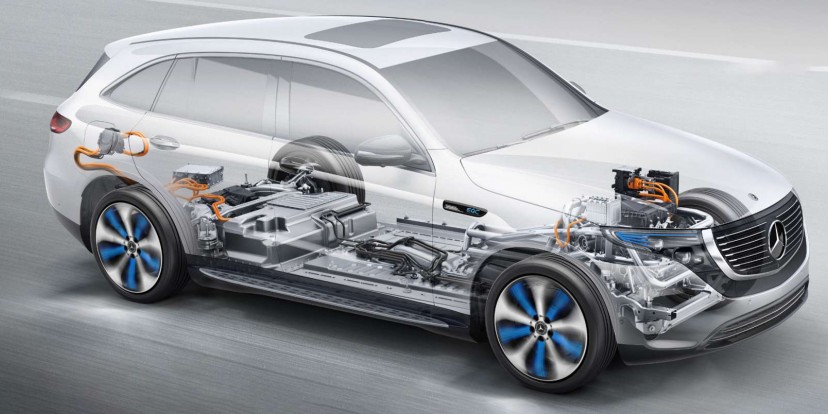

Examples of vehicles employing asynchronous induction motors include the Audi e-Tron SUV, Mercedes-Benz EQC, Tesla Model S, 3, X, and Y (front axles), as well as VW Group MEB platform vehicles on front axles.

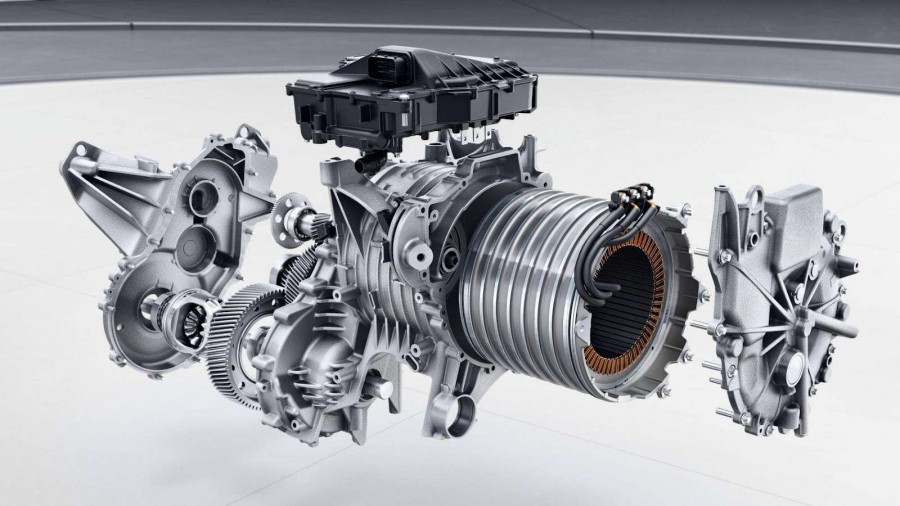

Induction motor used in Mercedes-Benz EQC

Induction motor used in Mercedes-Benz EQCSynchronous Permanent Magnet Motor

The key distinction between asynchronous and synchronous permanent magnet motors lies in how their magnetic fields are generated and aligned. Permanent magnet motors feature magnets in the rotor that produce a constant magnetic field, locking the rotor and stator fields in sync with no slip.

Permanent magnets immensely increase power density, delivering high power output in compact volumes, which makes these motors ideal for plug-in hybrids (PHEVs) where space is limited. However, the magnets rely on rare earth materials predominantly mined in China, raising ethical and supply concerns. Automakers are actively seeking to reduce their dependence on these materials.

Despite these challenges, synchronous permanent magnet motors lead in efficiency, often achieving 94–95%. They are typically the go-to choice for EVs with a single motor.

Advantages

- Very high efficiency

- Lower cooling demands

- High power density

Disadvantages

- Higher production costs

- Dependence on rare earth materials

- Potential risk of demagnetization

Hyundai Ioniq 5 permanent magnet motors

Hyundai Ioniq 5 permanent magnet motorsThis motor type powers vehicles such as the Hyundai Ioniq 5, Tesla Model S, 3, X, and Y (rear axles), VW Group MEB platform cars (rear axles), Jaguar I-Pace, Audi e-Tron GT, and Porsche Taycan.

Electrically Excited Synchronous Motor

To mitigate the downsides of rare earth magnets, some manufacturers like BMW, Renault Group, and Smart use electrically excited synchronous motors (EESM). Instead of permanent magnets, these motors generate the rotor’s magnetic field using rotor windings powered through brushes and slip rings.

BMW reports efficiency up to 93% with this design—close to permanent magnet motors—and eliminates rare earth material requirements and demagnetization risks. However, the use of brushes introduces concerns over long-term durability since these components wear out and may need replacement.

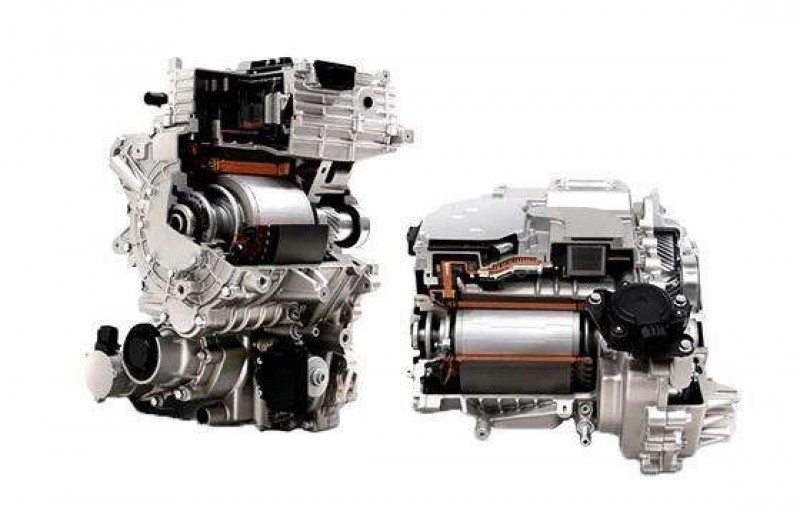

BMW electrically excited synchronous motor

BMW electrically excited synchronous motorAdvantages

- High efficiency

- Lower cost than permanent magnet motors

- No rare earth materials needed

- No demagnetization risk

Disadvantages

- Brush wear may affect long-term reliability

This motor is featured in the BMW iX3, iX, and i4 models, Renault Megane E-TECH, and SMART EQ vehicles.