The primary challenge slowing the complete adoption of electric vehicles is the current technology of high-voltage batteries. Although significant progress has been made over the last decade, the energy density of batteries remains far below that of liquid fuels. The ultimate goal in automotive research is to develop batteries with significantly higher energy densities than those currently available. This article reviews existing and emerging battery technologies to keep you informed.

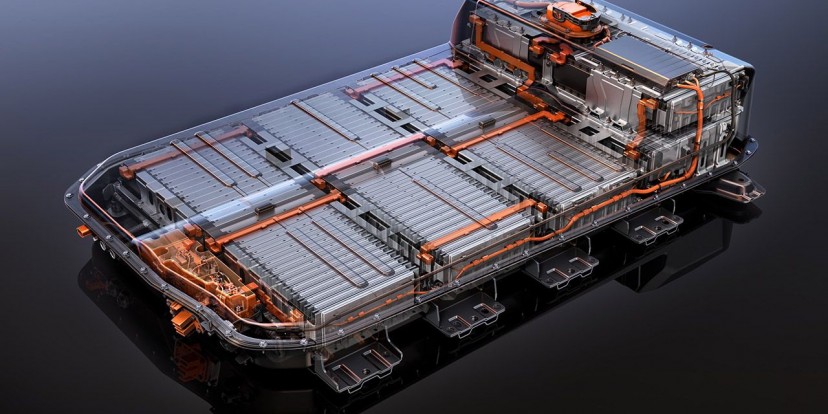

Lucid Air's advanced high voltage battery pack

Lucid Air's advanced high voltage battery pack

Current Technologies in Use

Lithium-ion Batteries with NCM and NCA Cathodes

Lithium-ion batteries have been around for about 30 years, first introduced commercially by Sony in the CCD-TR1 camcorder. These batteries operate by lithium ions moving between the anode and cathode. During discharge, lithium ions travel from the anode through liquid electrolytes to the cathode, while electrons flow through the external circuit and recombine in the cathode. During charging, this process reverses.

| Battery Type | Li-ion NCX |

|---|---|

| Specific Energy (Wh/kg battery) | 150-325 (High Nickel cathode, cell to pack, silicon anode) |

| Battery Endurance (cycles) | 500-1500 |

| Total Battery Pack Cost (€ / kWh) | 250-280 |

| Required Battery Weight for 500 km Trip at 130 km/h (kg) | 385-830 |

Currently, lithium-ion batteries with NCM (Nickel-Cobalt-Manganese) and NCA (Nickel-Cobalt-Aluminum) cathodes are predominantly used in electric vehicles. The composition of these materials affects the battery’s properties—for example, an NCM 712 battery contains 70% Nickel, 10% Cobalt, and 20% Manganese. Generally, a higher nickel content increases energy density, reducing the battery pack's weight and size.

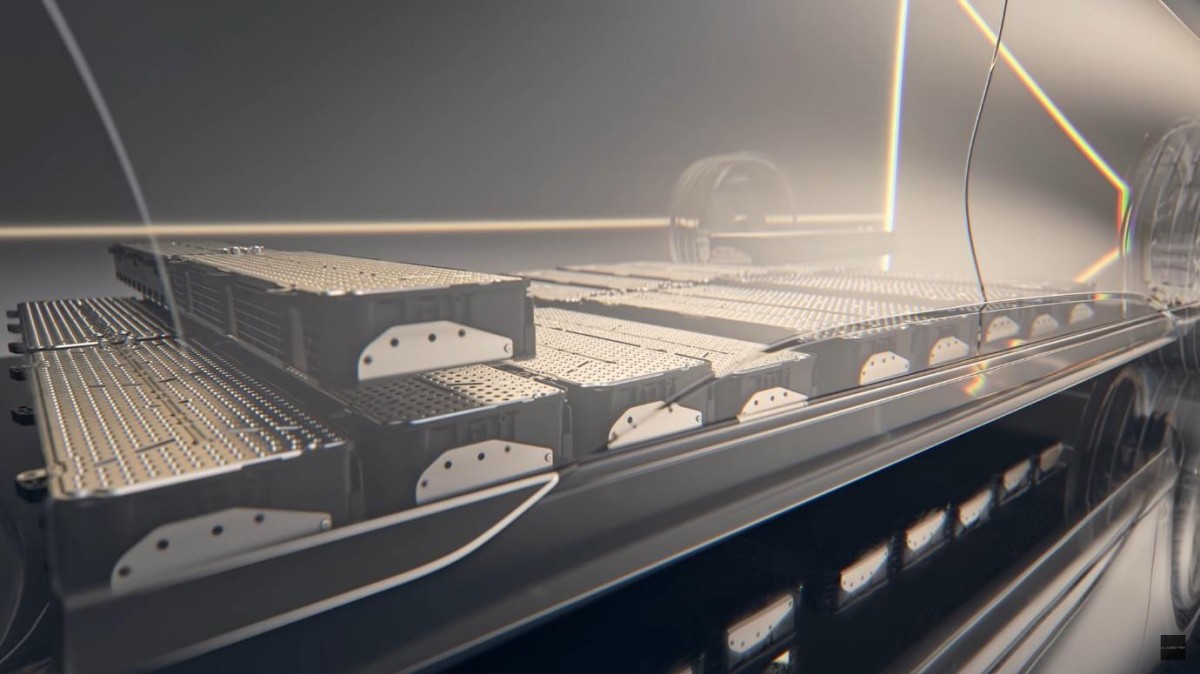

LG Chem NMC pouch cell

LG Chem NMC pouch cell

Due to cobalt’s scarcity and ethical concerns related to its mining, manufacturers aim to reduce or eliminate cobalt from the cathode chemistry. Combining a high-nickel cathode with silicon-enhanced anodes can push energy density up to 325 Wh/kg, suggesting this battery type is approaching its technological limits.

Lithium-ion Batteries with LFP Cathode

Lithium Iron Phosphate (LFP) is another cathode option for lithium-ion batteries. Although LFP batteries generally offer lower performance compared to NCM types, some manufacturers prefer them due to longer lifespan and the use of more abundant, less expensive materials. Their lower energy density results mainly from two factors.

CATL manufactured LFP battery pack from Tesla Model 3

CATL manufactured LFP battery pack from Tesla Model 3

Firstly, LFP batteries have a lower maximum voltage, resulting in fewer kWh per given capacity. Secondly, lithium ions move only in one spatial dimension (versus two in NCM batteries), which limits maximum discharge power. This makes LFP batteries less suitable for high-performance applications.

| Battery Type | LFP |

|---|---|

| Specific Energy (Wh/kg battery) | 120 |

| Battery Endurance (cycles) | >2000 |

| Total Battery Pack Cost (€ / kWh) | 200 |

| Required Battery Weight for 500 km Trip at 130 km/h (kg) | 1040 |

For example, Tesla uses LFP batteries in the base Model 3 due to their superior longevity and the ability to charge safely to 100%, which is actually recommended for these batteries.

Emerging Battery Technologies

Lithium-Air Batteries

Lithium-air batteries remain mostly in the research phase but show great promise, boasting specific energy close to that of liquid fuels at around 11.4 kWh/kg. In these batteries, lithium resides in the anode and air is present in the cathode, separated by an electrolyte. During discharge, lithium ions travel from anode to cathode and react with oxygen.

| Battery Type | Lithium-Air |

|---|---|

| Specific Energy (Wh/kg battery) | 11,400 |

| Battery Endurance (cycles) | Very low |

| Total Battery Pack Cost (€ / kWh) | Unknown |

| Required Battery Weight for 500 km Trip at 130 km/h (kg) | 11 |

However, challenges such as high charging temperatures that prevent fast charging and dendrite formation that drastically reduce cycle life confine lithium-air batteries to the laboratory stage. If technological hurdles and costs are overcome, they could render internal combustion engine vehicles obsolete.

Solid-State Batteries

Widely regarded as the “holy grail” of automotive batteries, solid-state technology is under intense development by major automakers. Unlike conventional lithium-ion batteries that use liquid electrolytes and separators, solid-state batteries replace these with a solid electrolyte.

| Battery Type | Solid-State |

|---|---|

| Specific Energy (Wh/kg battery) | 500-600* |

| Battery Endurance (cycles) | 1000* |

| Total Battery Pack Cost (€ / kWh) | Unknown |

| Required Battery Weight for 500 km Trip at 130 km/h (kg) | 200-250 |

Solid electrolytes under investigation include metallic and ceramic materials. While no production electric cars currently use solid-state batteries, the first models are expected within 2-3 years. These batteries potentially double the energy density of conventional lithium-ion cells and offer good cycle life, with future improvements anticipated.

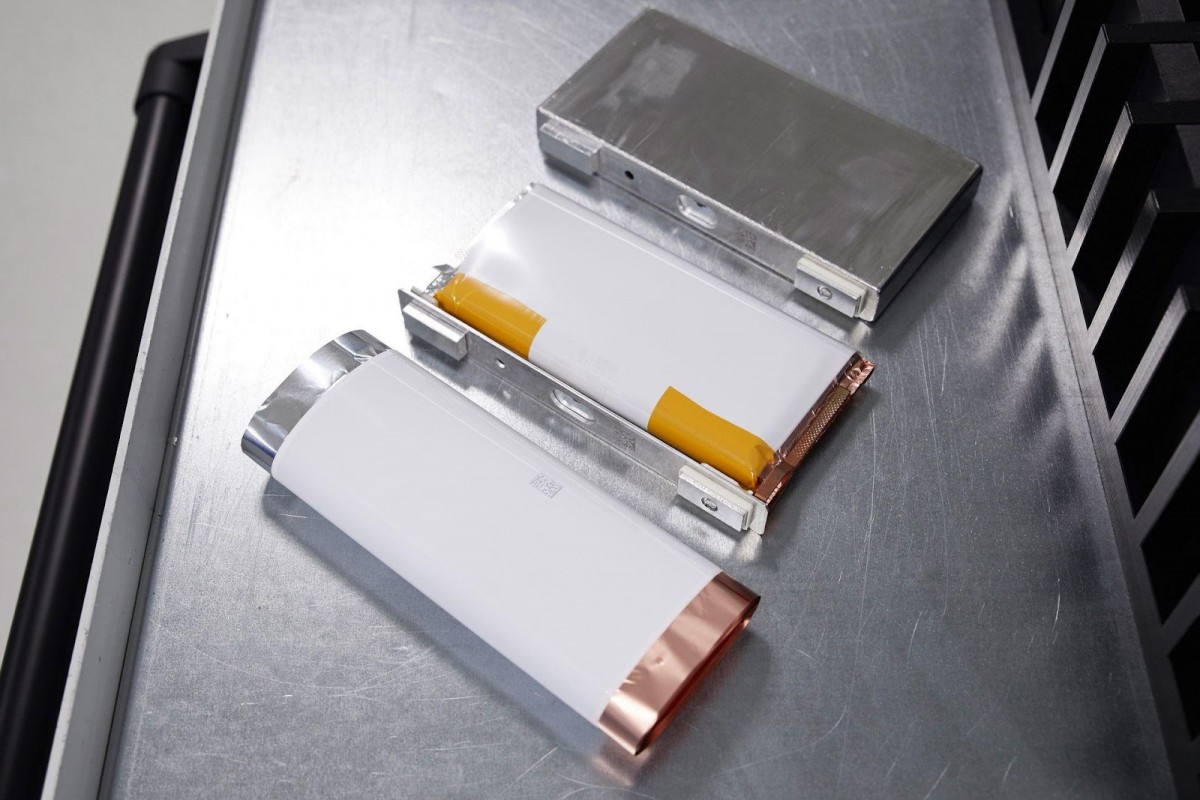

BMW solid state battery cell

BMW solid state battery cell