Electric vehicles (EVs) have not yet fully dominated the transportation sector largely due to current battery technologies. Despite significant advancements over the past decade, the energy density of these batteries still lags behind that of liquid fuels. The automotive industry's pursuit centers around developing batteries with markedly higher energy densities. This article reviews current and promising future EV battery technologies to update you on the latest developments.

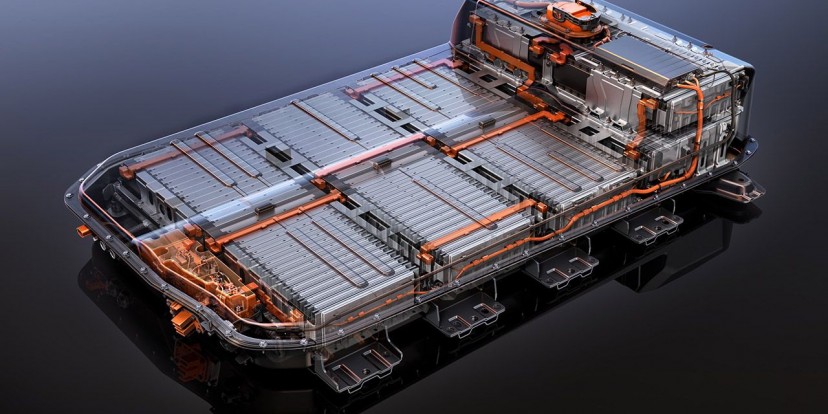

Lucid Air's advanced high voltage battery pack

Lucid Air's advanced high voltage battery packCurrent Battery Technologies

Lithium-Ion: NCM and NCA Cathodes

Lithium-ion batteries have been around for approximately 30 years, dating back to when Sony first commercialized the technology in its CCD-TR1 camcorder. The operation of a lithium-ion battery involves lithium ions moving between the anode and cathode. During discharge, lithium ions migrate from the anode to the cathode through liquid electrolytes, while electrons flow through the external circuit, recombining at the cathode. The process reverses during charging.

| Battery Type | Li-ion NCX |

|---|---|

| Specific Energy (Wh/kg battery) | 150-325 (High Nickel cathode, cell-to-pack, silicon anode) |

| Battery Endurance (cycles) | 500-1500 |

| Total Battery Pack Cost (€/kWh) | 250-280 |

| Required Battery Weight for 500 km Trip (kg) | 385-830 |

Currently, lithium-ion NCM and NCA batteries dominate the EV market. Here, N stands for Nickel, C for Cobalt, M for Manganese, and A for aluminum. Variations in the percentages of these materials yield different battery characteristics. For instance, an NCM 712 battery comprises 70% Nickel, 10% Cobalt, and 20% Manganese. Generally, increasing the Nickel content enhances energy density, positively impacting the battery pack’s weight and size.

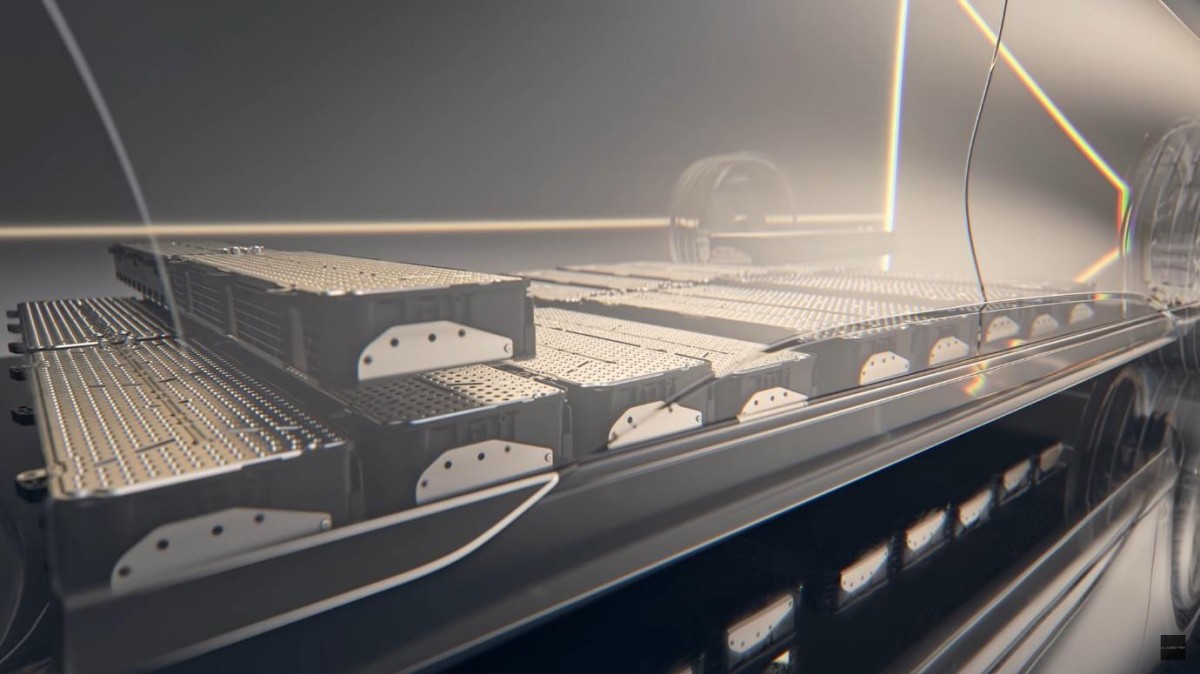

LG Chem NMC pouch cell

LG Chem NMC pouch cellDue to cobalt scarcity and ethical mining concerns, battery manufacturers increasingly seek chemistries with reduced cobalt content or aim for cobalt-free designs. The strategy of using a high Nickel cathode, integrating cell-to-pack arrangements, and including silicon in the anode can elevate energy density to approximately 325 Wh/kg, bringing these batteries closer to their technological limits.

Lithium-Ion: LFP Cathode

Another lithium-ion battery variant features Lithium Iron Phosphate (LFP) as the cathode. Although LFP batteries typically offer lower performance compared to NCM types, they are favored by some manufacturers for their longevity and the use of more affordable, widely available materials. Their lower energy density arises from two key factors.

CATL manufactured LFP battery pack from Tesla Model 3

CATL manufactured LFP battery pack from Tesla Model 3Firstly, the maximum voltage is reduced, which limits the energy capacity for the same capacitance. Secondly, in LFP batteries, lithium ions only move in one spatial dimension (as opposed to two in NCM batteries), constraining maximum discharge power. Consequently, LFP batteries are not ideal for high-performance applications.

| Battery Type | LFP |

|---|---|

| Specific Energy (Wh/kg battery) | 120 |

| Battery Endurance (cycles) | >2000 |

| Total Battery Pack Cost (€/kWh) | 200 |

| Required Battery Weight for 500 km Trip (kg) | 1040 |

This explains why Tesla reserves LFP battery chemistry for the base model of the Model 3. However, LFP batteries have notable advantages, including a longer lifespan and the ability to charge to 100% without issues, making this a recommended practice.

Future Battery Technologies

Lithium-Air

Lithium-Air batteries are currently in the research phase but are viewed as the most promising technology, potentially achieving energy densities comparable to liquid fuels at 11.4 kWh/kg. In this design, lithium serves as the anode, while air acts as the cathode, separated by an electrolyte. During discharge, lithium ions travel to the cathode, where they react with oxygen.

| Battery Type | Lithium-Air |

|---|---|

| Specific Energy (Wh/kg battery) | 11400 |

| Battery Endurance (cycles) | Very low |

| Total Battery Pack Cost (€/kWh) | Unknown |

| Required Battery Weight for 500 km Trip (kg) | 11 |

However, challenges such as high temperatures during charging hinder rapid recharging. Additionally, the formation of dendrites severely shortens battery life, currently confining this technology to laboratory settings. If these technological hurdles can be addressed and costs reduced, internal combustion engine vehicles may quickly become obsolete.

Solid State

Solid-state batteries are considered the ultimate goal in battery technology, with extensive research currently underway by major automotive players. Conventional lithium-ion batteries utilize liquid electrolytes and separators between the anode and cathode, whereas solid-state batteries replace these components with a solid electrolyte.

| Battery Type | Solid State |

|---|---|

| Specific Energy (Wh/kg battery) | 500-600* |

| Battery Endurance (cycles) | 1000* |

| Total Battery Pack Cost (€/kWh) | Unknown |

| Required Battery Weight for 500 km Trip (kg) | 200-250 |

Various materials, ranging from metallic to ceramic substances, are being investigated for use as solid electrolytes. Although no electric vehicles currently use solid-state batteries, the first production models are anticipated within the next 2-3 years. Solid-state batteries are projected to offer double the specific energy density of conventional lithium-ion batteries and a lifespan of around 1000 cycles, with the potential for improvements as research progresses.

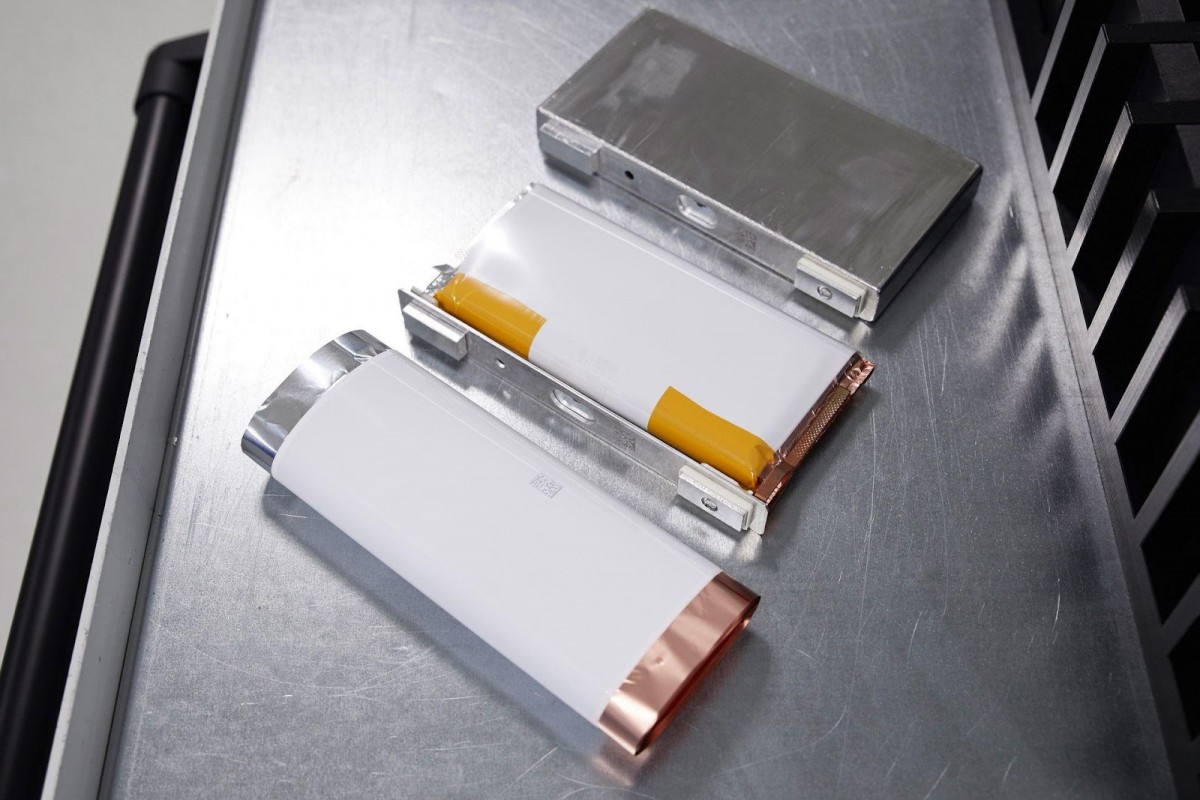

BMW solid state battery cell

BMW solid state battery cell